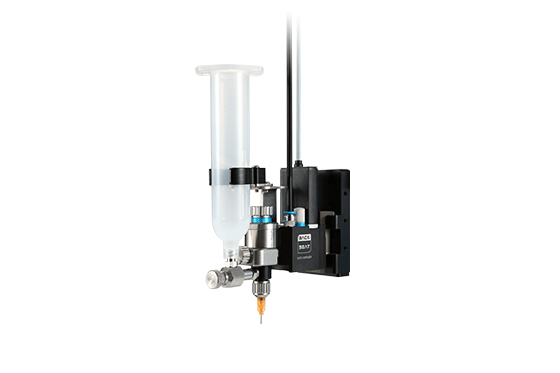

High-precision impact pin injection valve selection, Shenzhen Leica manufacturer

Release time:

2025-05-27 00:00

Source:

Leica Technology

There are many manufacturers of high-precision impact pin jet valves on the market, especially in the Pearl River Delta region, a high-tech industrial cluster. Many companies manufacture dispensing valve equipment, but most lack independent technology and have a gap compared to good dispensing equipment manufacturers. When encountering high-precision dispensing equipment, some manufacturers appear less capable.

How to choose a better high-precision impact pin jet valves ? Shenzhen Leica is a good choice. Shenzhen Leica is a technology company that manufactures dispensing valve equipment and provides solutions. After years of development, the company has established a good reputation in the industry market. The company has a good R&D team and adheres to the principles of continuous learning, innovation, and always putting customers first. In recent years, Shenzhen Leica has helped customers solve many problems, and customers have given Leica very good reviews. Therefore, the company has retained many long-term customers. Because of its good reputation, long-term customers recommend Shenzhen Leica to others. This word-of-mouth example proves the good reputation of Shenzhen Leica.

Leica high-precision impact pin jet valves is a company that operates with integrity and pursues innovative development. It takes the interests of customers as its responsibility and strives to provide customers with better and higher-quality products. Welcome to Shenzhen Leica to learn more.

Related News

The stability of the piezoelectric valve dispensing process directly determines product quality. Common issues such as uneven dispensing, stringing, and glue leakage can be effectively addressed through parameter adjustments and optimized matching. Laike’s piezoelectric valves support multi-level parameter adjustments, enabling precise matching of pressure, injection frequency, and nozzle aperture according to the specific characteristics of different fluids.

Blocking the hole is Piezoelectric valve The most common failures in dispensing operations are often caused by fluid solidification, residual impurities, and nozzle wear, which directly affect dispensing accuracy and efficiency. Given the structural characteristics of piezoelectric valves, these issues can be addressed in three steps: “diagnosis—cleaning—inspection.” First, stop the machine and visually inspect the nozzle for obvious glue deposits or foreign objects, determining whether the blockage is temporary or a persistent issue caused by nozzle wear.

Piezoelectric valve: A highly efficient core component in the field of precision automation.

Piezoelectric valves leverage the inverse piezoelectric effect of piezoceramics to achieve precise control. With advantages such as low energy consumption, silent operation, and rapid response, they have become critical equipment in the field of precision manufacturing. Unlike traditional solenoid valves, which require continuous current to maintain their operating state, piezoelectric valves consume far less energy. Moreover, they operate without generating heat or producing magnetic interference, making them well-suited for high-demand operational environments.