There are no bad dispensing valves, only dispensing valve manufacturers who don't work hard enough

Release time:

2025-08-21 09:12

Source:

Leica Technology

There are many dispensing valve manufacturers on the market now Dispensing valve manufacturers There are countless dispensing valve manufacturers, thanks to the continuous development and improvement of science and technology in our country, allowing our domestic technology to gradually develop. However, many customers still encounter some difficulties when choosing. Among so many manufacturers, there are good ones and bad ones, and it is difficult to judge the quality from the surface, making customers afraid of making the wrong choice.

In fact, the dispensing valves produced by numerous dispensing valve manufacturers are of several types, with similar functions and principles. However, due to the different strengths of each manufacturer, the equipment produced by each manufacturer will certainly be different. It is difficult for customers to judge which one is good and which one is bad when choosing. I believe that when choosing dispensing valve equipment, you should do more preliminary research, understand well-known and reputable companies in the industry, thus eliminating less reputable small companies. Then, choose a satisfactory one from the selected companies. This is an effective selection method. Choosing a good manufacturer ensures good dispensing valve equipment.

Leiko dispensing valve manufacturer is an ambitious company with years of experience in the production and R&D of dispensing valves, and enjoys a good reputation among numerous customers, making it a worthwhile choice.

Related News

How can daily maintenance help extend the service life of a valve body?

As a precision component that operates at high frequency, the precision dispensing valve requires scientific daily maintenance to extend its service life and maintain dispensing accuracy. Shenzhen Laike Technology has compiled the following key maintenance points for you: Daily cleaning is crucial and should not be overlooked. After finishing work, promptly remove any residual adhesive from the exterior of the valve body, especially around the nozzle and plunger area. Once cured, adhesive can cause blockages or wear, affecting subsequent use. It is recommended to gently wipe with a suitable cleaning solvent, taking care not to damage the seals. Regularly inspect sealing components—seals and other parts will naturally degrade over time during prolonged operation. We recommend checking their condition periodically based on usage frequency. If you notice signs of hardening or wear, replace these components promptly to prevent adhesive from seeping into the valve body and causing more serious damage.

The stringing issue during the dispensing process is often closely related to fluid properties, equipment parameters, and process settings. Drawing on years of industry experience, Shenzhen Laike Technology has compiled and optimized key points for you: Fluid temperature control is crucial. Proper heating can reduce the viscosity of the adhesive, improve its flowability, and minimize stringing and trailing. Laike Technology’s dispensing valves can be equipped with precision temperature-control modules to ensure that the fluid remains in a consistently stable working state. The back-suction parameters must be finely adjusted. The negative-pressure back-suction applied at the moment the glue dispensing stops can effectively cut off the adhesive flow, preventing dripping and stringing. We recommend gradually adjusting the amount and speed of back-suction according to the adhesive’s viscosity until you find the ideal balance.

Contact Dispensing vs. Non-Contact Jetting Valves: How Should You Choose for Micron-Level Processes?

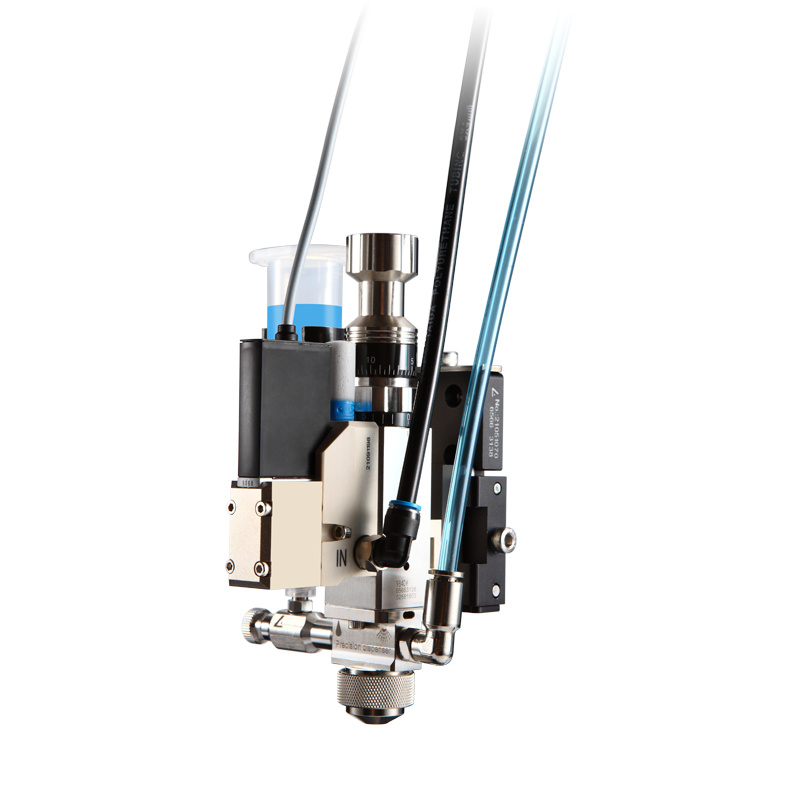

Contact dispensing involves the needle making physical contact with the substrate surface to apply the fluid. Its main advantage lies in its strong adaptability to high-viscosity fluids and relatively controllable dispensing process. However, since it requires coordinated movement along the Z-axis, the dispensing speed is limited. Additionally, there is a risk of the needle colliding with and damaging the workpiece or deforming the needle itself. Therefore, careful evaluation is necessary when applying this method in miniaturized packaging scenarios. In contrast, non-contact jetting valves use a driving mechanism to rapidly spray adhesive onto the workpiece surface without any physical contact between the needle and the substrate. This feature makes them ideally suited for substrates with uneven surfaces or those that are fragile. They excel in micron-scale processes such as bottom-fill applications for chips and precision coating. The jetting method eliminates the need for Z-axis movement, significantly boosting production efficiency while also avoiding common issues associated with contact dispensing, such as stringing and trailing.

The stability of the piezoelectric valve dispensing process directly determines product quality. Common issues such as uneven dispensing, stringing, and glue leakage can be effectively addressed through parameter adjustments and optimized matching. Laike’s piezoelectric valves support multi-level parameter adjustments, enabling precise matching of pressure, injection frequency, and nozzle aperture according to the specific characteristics of different fluids.

Blocking the hole is Piezoelectric valve The most common failures in dispensing operations are often caused by fluid solidification, residual impurities, and nozzle wear, which directly affect dispensing accuracy and efficiency. Given the structural characteristics of piezoelectric valves, these issues can be addressed in three steps: “diagnosis—cleaning—inspection.” First, stop the machine and visually inspect the nozzle for obvious glue deposits or foreign objects, determining whether the blockage is temporary or a persistent issue caused by nozzle wear.

Piezoelectric valve: A highly efficient core component in the field of precision automation.

Piezoelectric valves leverage the inverse piezoelectric effect of piezoceramics to achieve precise control. With advantages such as low energy consumption, silent operation, and rapid response, they have become critical equipment in the field of precision manufacturing. Unlike traditional solenoid valves, which require continuous current to maintain their operating state, piezoelectric valves consume far less energy. Moreover, they operate without generating heat or producing magnetic interference, making them well-suited for high-demand operational environments.