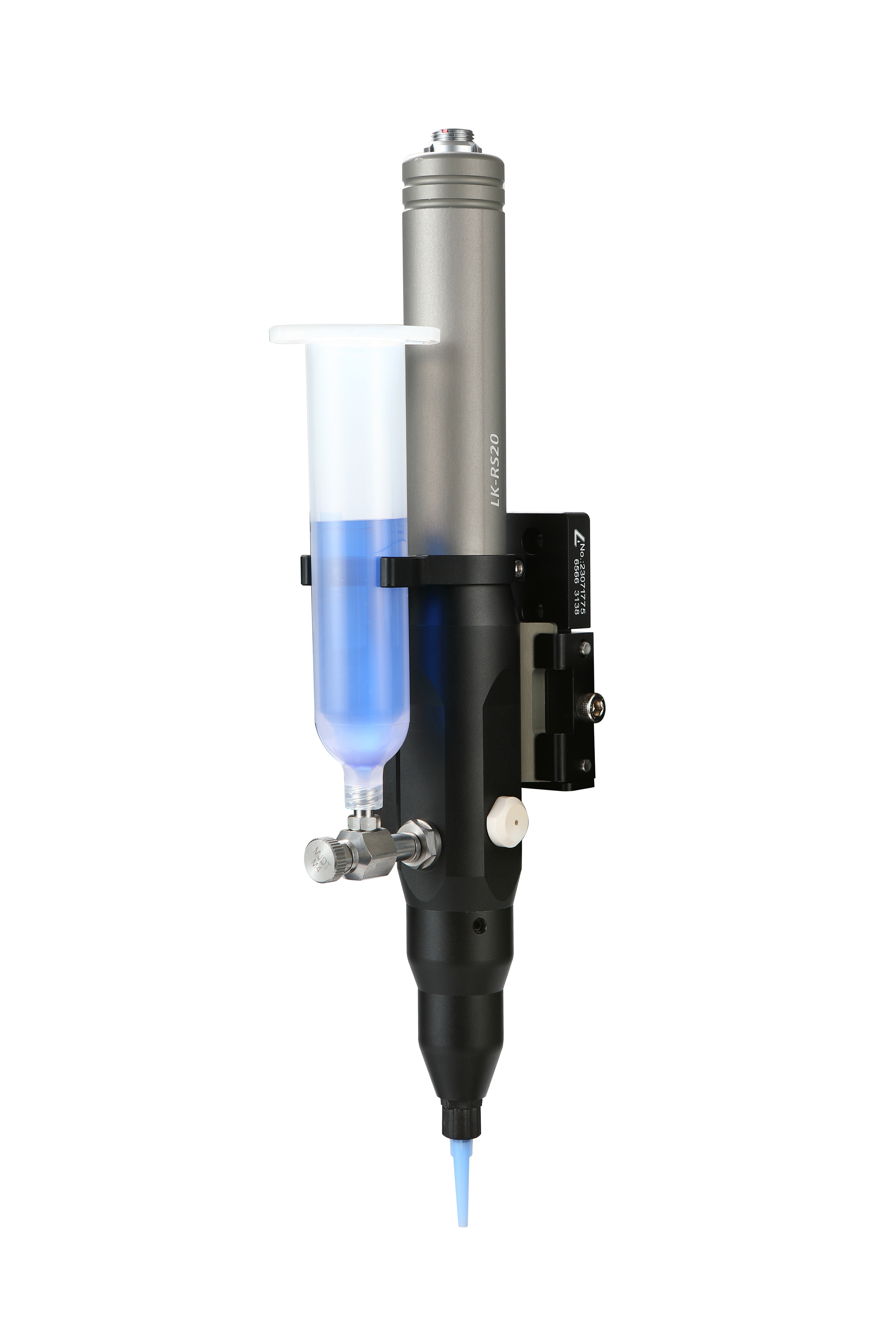

Screw valve LK-RS30

The LK-RS30 is an industrial-grade, high-precision screw valve launched by Laike. It uses a tungsten carbide metal screw core component and is specifically designed for precision metering of ultra-high viscosity fluids. Through an innovative mechanical seal structure and pressure compensation system, it achieves ultra-high volumetric accuracy, meeting the stringent demands of industrial dispensing.

Affiliated Classification:

Screw valve

Keywords:

Screw valve LK-RS30

Product Enquiry

- Product Description

- Advantage

- Specificities

- Appliance

-

The LK-RS30 is an industrial-grade, high-precision screw valve launched by Laike. It uses a tungsten carbide metal screw core component and is specifically designed for precision metering of ultra-high viscosity fluids. Through an innovative mechanical seal structure and pressure compensation system, it achieves ultra-high volumetric accuracy, meeting the stringent demands of industrial dispensing.

-

Fine and micro glue dispensing, controllable amount of glue, no noise, free start and stop, and even rotational speed

The controller interface can achieve multiple mode switching operations -

LK-RS30 precision screw valve precision volumetric metering and conveying product, suitable for various high-precision quantitative conveying occasions, adopts a spiral structure design to achieve quantitative conveying function. The transportation process does not have a shear effect on the medium and does not affect its characteristics. At the same time, the adhesive can be easily broken through the reverse suction and vacuum suction functions of the motor, perfectly solving the problems of dripping and wire drawing during the dispensing process.

-

Chip Silicon Mai Wafer LCD OLED Photovoltaic New Energy Medical

preceding page

next page

preceding page

next page

Hot Products

Product Inquiry